Services

Plating Services

Electroless Nickel Plating

- Tank capacity of 72” by 42” by 24″

- High, Mid, Low Phos

- Nickel Boron Nitride

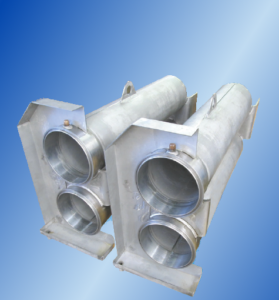

Electroless nickel plating of a complicated weldments

Zinc Nickel Plating & Zinc Phosphate Coating

- Tank capacity of 78” by 47” by 46”

- Plating characteristics, such as abrasion, chemical, and corrosion resistance

- Several pre-plating, post-plating operations

Stainless Steel Finishing Services

Electro Polish, Passivation, & Metal Pickling

- Precision nitric passivation of stainless steel

- Metal Pickling services for a wide range of industries

- Accommodating products with a maximum measurement

of 10 feet in length, 4 feet in width, 44 inches in height,

and up to 4,000 lbs. in weight - Glass beading capacity of 4’ by 30” by 30”

- Electro polish 30” by 30” by 30”

Vibratory Finishing Services

- Specializing in precision parts with special consideration for flatness tolerances

- Our aggregate tumbling,and vibratory processes can accommodate productsup to 12” long, 4” wide, and 5” high

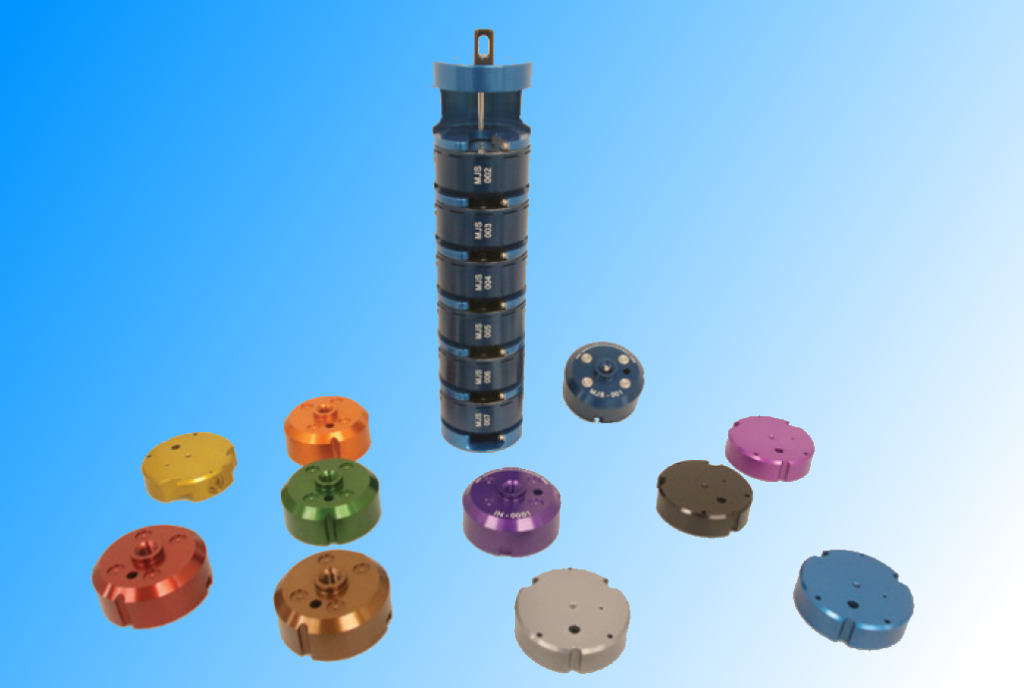

Aluminum Anodizing Services

- Type two and type three hard anodizing, with a 10’ by 3’ by 6’ tank capacity

- We can accommodate most aluminum alloys

- Several pre-plating and post plating services

Powder Coating Services

- Full line of powder paints

- Batch type powder coating for over 10 distinct industries

- 20’ by 8’ by 8’ batch baking oven

- We can apply the powder coating of your choice, thick film and urethane

- Features including:

— abrasion resistance

— insulation

— thermal protection

— baked

— electrostatic

— spray applications - Substrates:

— aluminum

— metal

- Features including:

- Pre-coating services

- Coating removal

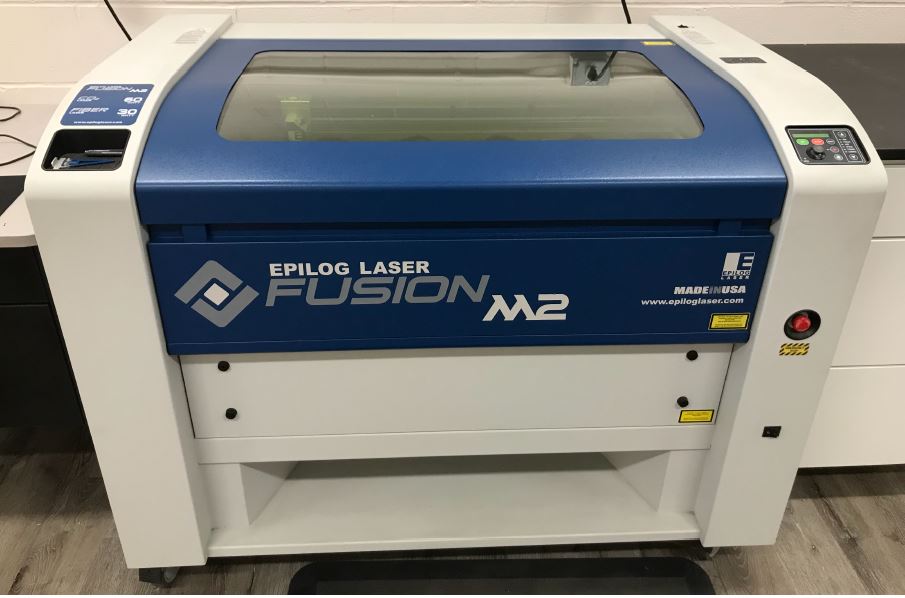

Laser Engraving, Laser Etching & Assembly Services

- Featuring a 3 axis, 60 watt, CO2 laser,30 watt fiber, with a 32” by 20” by 20” bed

- Specializing in bar-coding parts and decorative sheet metal work

- UID marking, serializing, and contour engraving capabilities

- We work with a variety of materials, including anodized aluminum, stainless steel, rubber, glass, and wood

Sandblasting and Glass Bead Blasting Services

- Silica free and glass bead blasting with a 20’ by 20’ by 20’ blasting booth and a 9,000 lb. lifting capacity. IMF features a variety of sand and media finishing services for a diverse range of industries and applications.

Aerospace

Automotive

Consumer Goods

Electrical

Electronics

Medical

Military

Pharmaceutical

Refrigeration

Robotics

Semiconductor

Agricultural Equipment |

Sand Blasting

Glass Beading

Media Blasting

FDA – Compliant – Food And Drug Administration

ISO – Compliant – International Organization for Standardization

Mil-Spec – Compliant – Military Specifications

Specialty Production Shop

Prototype

Low Volume

Small Run

High Volume

Large Run

Long Run

Large Scale Production Volume Run

Portfolios

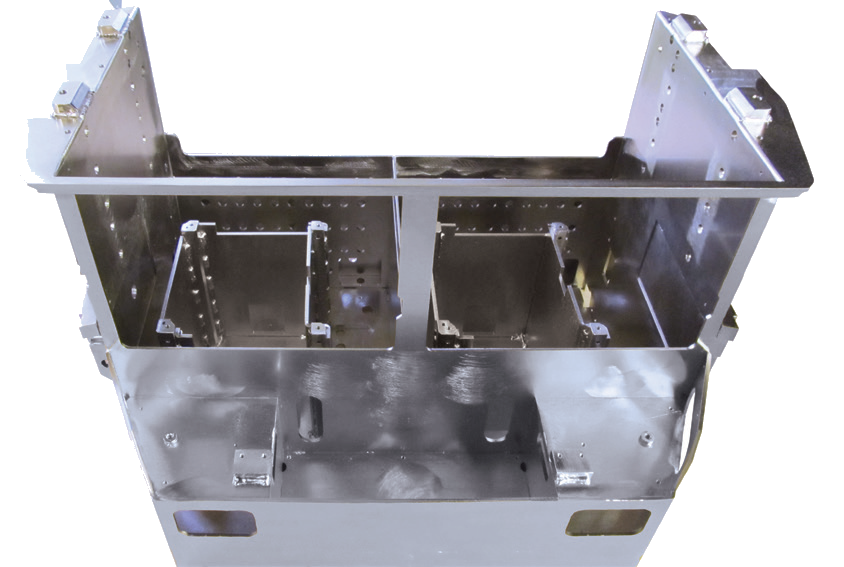

Electroless Nickel Plating of Complicated Weldments

for Equipment Used in a Clean Room Environment in the Semi-Conductor Industry

Working with ASTM A1011 as a base material, IMF conducted electroless nickel plating of a steel weldment intended for use in a semiconductor industry cleanroom environment. The applied material thickness was 0.0004” to 0.0006”, and the part measured 29” long, 18” wide, 19” high, and weighed 175 lbs. The final component met ASTM B733 standards and was free of all streaks and contamination, and therefore was ready for use in a cleanroom application for the semiconductor industry.

| Capabilities Applied/Processes: | Electroless Nickel Plating |

| Base Material: | ASTM A1011 |

| Material Thickness Applied: | 0.0004″-0.0006″ |

| Product Length: | 29″ |

| Product Width: | 18″ |

| Product Height: | 19″ |

| Product Weight: | 175 lbs |

| Special Feature: | Part Must be free of all streaks and contamination |

| Industry for Use: | semi-conductor |

| Volume: | 12/week |

| Standards Met: | ASTM B733 |

| Product Name: | Storage Frame |

| Product Description | Steel Weldment |

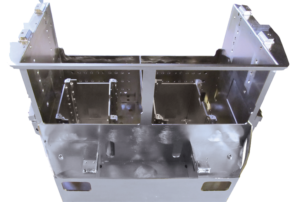

Pickle and Passivation of Stainless Steel Fabrications

For Equipment Used in the Transportation Industry

IMF pickels stainless steel fabrications for use in transportation industry. Pickling & passivating various sizes of 304 stainless steel fabrications, ensuring that each component adhered to ASTM, A967, and AMS 2700 standards. The end product was delivered to the client within 24 hours, and was put to use in the transportation industry.

| Capabilities Applied/Processes: | pickel and passivate |

| Product Length: | various |

| Product Width: | various |

| Product Height: | various |

| Product Weight: | various |

| Material: | 304 ss |

| Industry for Use: | Semi Conductor |

| Volume: | 6/week |

| Delivery Time: | 24 hrs |

| Standards Met: | ASTM A967 AMS 2700 |

| Product Name: | Clean Air Assembly Kits |

| Product Description | Air Filtration unit for clean room |

Vibratory Deburring of Steel Rings

Used in the Automotive Industry

IMF conducted deburring and rust preventative operations for an automotive transmission ring, and produced 6,000 units per day. Made from 1040 steel, the material was 0.045” in thickness, and the final transmission ring measured 8” in outside diameter. Tight tolerances were upheld through the process, with a +/- .010” tolerance to maintain flatness, and a +/- .0006” tolerance while deburring. The transmission ring order was then packaged in client-supplied packaging, and delivered.

| Capabilities Applied/Processes: | Deburring |

| Tightest Tolerance: | maintain flatness < .010″ Remove burr to < 0.0006″ |

| Material Thickness: | 0.045″ |

| Product Dimensions | 8″ OD |

| Base Material: | 1040 |

| Pacakging: | provided by customer |

| Secondary Operations Applied: | rust preventative |

| Industry for Use: | Automotive |

| Volume: | 6000/day |

| Product Name: | Transmission Ring |

| Product Description: | Transmission Ring |

Our Work.

about us.

Industrial Metal Finishing, Inc. is a New York-based corporation formed in 2001. Our team has over 20 years of expertise in metal finishing and anodizing. We specialize in Electroless Nickel Plating, and are known for consistently high quality processing of complex parts. Attention to detail in every stage of processing allows our customers to rely on us to provide exceptional results every time. We are capable of managing a small batch of sample parts for a development order or large volume production runs, and are committed to the highest quality and superior customer service.

Our wide range of capabilities means you can count on us to provide all your metal finishing needs, including removal of prior plating or coatings, chemical cleaning, surface polishing\finishing, and a final enduring finish. Being flexible to our customers’ needs is a key value at Industrial Metal Finishing, Inc. We can provide 24 hour turn around on many parts and will work to coordinate effforts to provide the most efficient processing to meet your time table.

Located in the Southern Tier of Western New York, we are conveniently located within three hours of Pittsburgh, PA, Cleveland, OH, and Syracuse, NY.

Get in Touch

Where to Find Us

1070 ALLEN STREET

JAMESTOWN, NY 14701